Description

Description

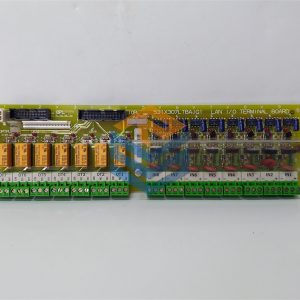

I/O Terminal Blocks are generic wiring bases that provide

module mounting, backplane communications, and terminals

for user connections. Two modules can be installed on one

terminal block. Modules screw onto the terminal block for

vibration resistance. Modules can be removed without

disturbing field wiring.

For each I/O module, there are three isolated groups of

common terminals: the A group (internally connected together)

and B group (internally connected together) are typically used

for power connections. The E group has five common terminals

that are internally tied together and isolated from the power

and point terminals. They can be used as needed for

application wiring. Terminals 1 – 16 are used for I/O wiring.

Each terminal accommodates up to one AWG #14 (2.1 mm2) or

two AWG #18 (0.86mm2) through AWG #22 (.35 mm2) wires.

Use copper wire rated for 90 degrees C. Recommended

terminal torque is 4.5 in/lbs. The maximum current through

any one terminal is 10 Amps.

I/O Terminal Block IC670CHS102 permits hot insertion/

removal of modules without affecting the Bus Interface Unit or

other modules in the I/O Station. Hot insertion/removal can

only be performed in non-hazardous locations.

Compatibility

I/O Terminal Block IC670CHS102 has a projecting alignment

slot at each module position. It must be used with modules

whose catalog number suffix is J or above. These modules have

a projecting tab that fits into the alignment slot.

Bus Interface Unit version 2.1 or later is required for hot

insertion/removal of modules in the I/O Station.

Mixing IC670CHS10x terminal blocks with IC670CHS00x

terminal blocks in the same I/O station is not recommended.

Caution

I/O Terminal Blocks IC670CHS102 and IC670CHS002B or later

have a metal grounding strip underneath. They must be used

with a grounded conductive DIN rail. Do not use these

terminal blocks with A version I/O Terminal Blocks or BIU

Terminal Block IC670GBI001, which do not have a metal

grounding strip; the system would have poor noise immunity.

Installing a Terminal Block on a DIN Rail

A new I/O Terminal Block is protected by a pair of sturdy labels.

Keep these labels in place while installing the terminal block to

prevent environmental contamination of block components.

Follow the steps below to install the terminal block on a DIN rail.

1. Tilt the I/O Terminal Block and position it over the rail,

catching the rail behind the tabs in the terminal block.

2. Pivot the terminal block downward until the

spring-loaded latches click into place.

tabs DIN rail

46413

3. Tighten the DIN rail clamp screw. Recommended torque

is 4 in/lbs to 6 in/lbs.

46484

Tighten

Removing the I/O Terminal Block from a DIN Rail

If Auxiliary Terminal Blocks are present, they must be taken off

before the I/O Terminal Block can be removed from the DIN

rail. Then follow the steps below to remove the I/O Terminal

Block.

1. Loosen the DIN rail clamp screw.

2. Insert a small flat-blade screwdriver into the upper latch

and pry it outward.

3. Pull up gently on the top of the terminal block to

disengage the upper latch from the rail. Insert the

screwdriver into the lower latch and pry it outward to free

the terminal block.

IC670CBL001

All prices listed on the official website are subject to confirmation by contact: Wu Jiedong (manager).

Our product: brand new original packaging

Our warranty: All new or repaired parts have a 12 month warranty period beginning

Our payment: 100% telegraphic transfer of inventory items before shipment, conditions can be proposed!

If you have any downtime spare parts that you cannot find, please feel free to call or use email to contact me. If there are issues that the product cannot solve, please contact me. Product prices can be negotiated. Please do not consider contacting me!