FOXBORO FBM202 is a module from the Foxboro series widely used in industrial automation, instrumentation, and machinery manufacturing. Here is a detailed explanation of its parameters, specifications, dimensions, weight, series, features, and functions in English:

Parameters and Specifications:

Model: FBM202.

Input Range: Typically covers a wide range of analog or digital signals, depending on the specific configuration and application.

Communication Protocols: Supports various communication protocols such as Modbus, Profibus, and Foundation Fieldbus, enabling seamless integration with other industrial automation systems.

Power Supply: Typically operates on a standard voltage range, such as 24VDC.

Dimensions and Weight:

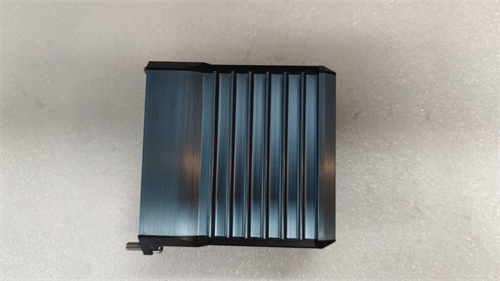

Dimensions: Typically measures around 100mm x 50mm x 70mm (or approximately 4 inches x 2 inches x 2.75 inches), but dimensions may vary slightly depending on the specific model or version.

Weight: Typically lightweight, suitable for easy installation and integration into industrial equipment. However, the exact weight may vary, so it’s recommended to refer to the manufacturer’s specifications for the most accurate information.

Series:

FBM202 belongs to the FBM series of Foxboro products, which are designed for use in industrial control systems.

Features:

High Accuracy and Reliability: The FBM202 module is designed to provide high-accuracy measurements and reliable performance in industrial environments.

Flexible Configuration: It offers flexible configuration options, allowing users to customize the module to meet specific application requirements.

Robust Design: With its robust design, the FBM202 module can withstand harsh industrial conditions and maintain stable performance.

Functions:

The FBM202 module serves as a critical component in industrial automation systems. It receives and processes input signals from sensors, converts them into appropriate output signals, and controls actuators or other devices accordingly. It also enables data communication and sharing with other control modules or systems, facilitating seamless integration and coordinated operation within the overall automation system.