Description

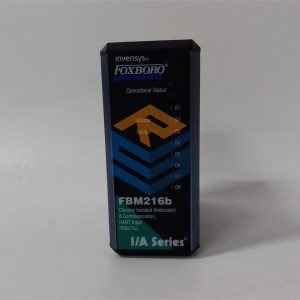

FOXBORO P0926KP

With the increasing expansion of PLC application field, PLC technology and its product structure are constantly improving, with increasingly powerful functions and higher cost performance.

In terms of product scale, it develops towards two poles. On the one hand, we should vigorously develop small and ultra-small PLCs with faster speed and higher cost performance. To meet the needs of single machine and small automatic control. On the other hand, it will develop towards large PLC with high speed, large capacity and perfect technology. With the higher and higher requirements of complex system control and the continuous development of microprocessor and computer technology, people have higher and higher requirements for the information processing speed of PLC and the user memory capacity.

Development towards communication networking

PLC network control is the current trend of control system and PLC technology development. The networking communication between PLC and PLC, and the networking communication between PLC and upper computer have been widely used. At present, PLC manufacturers are developing their own dedicated communication modules and communication software to strengthen the networking capability of PLC. PLC manufacturers are also negotiating to specify common communication standards to form a larger network system. PLC has become an indispensable part of DCS.

Develop towards modularization and intelligence

In order to meet the needs of various control systems in industrial automation, PLC manufacturers have developed many new devices and modules in recent years, such as intelligent I/O modules, temperature control modules and special intelligent modules specially used to detect PLC external faults. The development and application of these modules not only enhance the functions, expand the application scope of PLC, but also improve the reliability of the system.

Diversification and standardization of programming languages and programming tools

The coexistence, complementarity and development of multiple programming languages is a trend of PLC software progress. PLC manufacturers are increasingly close to MAP (Manufacturing Automation Protocol) while making hardware and programming tools updated frequently, rich and diverse, and improving their functions, so as to standardize and standardize the basic components of PLC, including input and output modules, communication protocols, programming languages and programming tools.

Manufacture and characteristics of TRICONEX TRICON 5451

TRICONEX TRICON 5481 Differences

ENI OEM-2000-01M1 shutdown power supply

MKS ENI SPECTUM B-5002 power supply

ENI DCG-200Z power supply

OEM-2000 2000w 13.56mhz power supply

ENI RFC-5MW power supply

ENI OPTIMA DCG-200Z DCG-200E DCG-200A DCG-100 power supply

ENI MKS GEW3540 transmitter

ENI GHW-85A transmitter

MKS ENI Spectrum 5303-00 RF

ENI OEM-1250 technical parameters

UFC921A101 Technical Article

DDLS 200/200.2-60 Technical parameters

5X00497G01 manufacturing and characteristics

1C31232G02 Technical article

MVI56-MNET installation and transportation

NDBU-95C DCS system spare parts

PSM-E20 design principle

All prices listed on the official website are subject to confirmation by contact: Wu Jiedong (manager).

Our product: brand new original packaging

Our warranty: All new or repaired parts have a 12 month warranty period beginning

Our payment: 100% telegraphic transfer of inventory items before shipment, conditions can be proposed!

If you have any downtime spare parts that you cannot find, please feel free to call or use email to contact me. If there are issues that the product cannot solve, please contact me. Product prices can be negotiated. Please do not consider contacting me!