Description

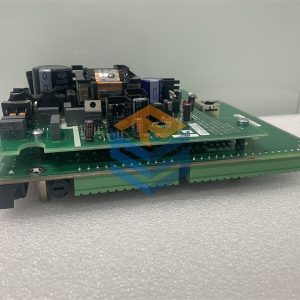

The DS200DCFBG1BLC is a power supply board manufactured by General Electric (GE) designed for the Mark V series, which is a line of optional and replacement boards for GE industrial applications. Here’s a possible breakdown of its production process:

Possible Production Stages:

-

Component Sourcing:

- GE sources high-quality electronic components from reliable suppliers that meet their specifications. These components might include:

- High-grade transformers and inductors for voltage regulation and power conversion.

- Capacitors for filtering and stabilizing power supply.

- Semiconductor components like diodes, transistors, and integrated circuits (ICs) for power management and control.

- Printed circuit board (PCB) already fabricated according to GE’s design (discussed in the next stage).

- GE sources high-quality electronic components from reliable suppliers that meet their specifications. These components might include:

-

Printed Circuit Board (PCB) Assembly:

- The PCBs are likely pre-fabricated by a specialized PCB manufacturer according to GE’s specifications. This may involve multiple layers with etched circuitry and drilled holes for precise component placement.

- In a dedicated GE facility or by a contracted assembler, the procured electronic components are then populated onto the PCBs using:

- Automated pick-and-place machines for precise component placement.

- Soldering techniques like reflow ovens or wave soldering to securely connect components to the PCB.

-

Component Inspection and Testing:

- After assembly, each PCB undergoes rigorous inspection to ensure proper component placement and soldering quality.

- Automated or manual testing equipment might be used to verify the electrical functionality of individual components and the overall performance of the PCB.

-

Board Assembly and Integration:

- The populated PCB is integrated into the housing of the DS200DCFBG1BLC. This may involve:

- Attaching the PCB to a heat sink to dissipate heat generated by electronic components.

- Adding connectors for power input and output connections.

- Installing a protective cover or enclosure for safety and environmental protection.

- The populated PCB is integrated into the housing of the DS200DCFBG1BLC. This may involve:

-

Final Testing and Quality Control:

- The complete DS200DCFBG1BLC undergoes final testing to ensure it meets all performance and safety specifications. This likely involves:

- Electrical testing to verify power output voltage and current levels.

- Functional testing to confirm the board operates as intended within the Mark V system (if possible at this stage).

- Safety testing to ensure the board meets relevant safety standards.

- The complete DS200DCFBG1BLC undergoes final testing to ensure it meets all performance and safety specifications. This likely involves:

-

Packaging and Shipping:

- Once all tests are passed, the DS200DCFBG1BLC is labeled according to regulations and securely packaged for shipment. It’s then shipped to distributors, service centers, or end users who require replacement parts for the Mark V series.

Materials and Manufacturing Technology:

GE likely adheres to high-quality standards in material selection and manufacturing processes to ensure the reliability and performance of the DS200DCFBG1BLC. Here are some possibilities:

- High-grade electronic components: Selected for long service life, reliability, and efficient power conversion.

- Lead-free soldering: Aligns with environmental regulations and promotes sustainability.

- Automated assembly and testing equipment: Ensures consistent quality and efficiency.

- Surface-mount technology (SMT): Likely used for efficient PCB assembly due to the miniaturization of electronic components.

- Advanced quality control procedures: Implemented throughout the process to identify and rectify any defects.

Finding More Specific Information:

Obtaining in-depth details about the exact production process for the DS200DCFBG1BLC might be challenging due to its potentially proprietary nature. Here are some suggestions for further exploration:

- GE Support: While they might not disclose confidential details, contacting GE technical support or a relevant GE service department could provide general information about the Mark V series and replacement parts.

- Technical Documentation: If available, search for data sheets, manuals, or service guides related to the DS200DCFBG1BLC or the Mark V series. These resources might offer insights into the board’s functionality, components, and recommended replacement procedures.

- Third-Party Resources: Look for online resources or forums related to GE industrial automation or Mark V systems. Discussions or shared knowledge from experienced users might provide indirect insights into the production process.

Remember that manufacturers often guard confidential details about their production processes. The information above provides a possible scenario based on common practices in the electronics manufacturing industry.

All prices listed on the official website are subject to confirmation by contact: Wu Jiedong (manager).

Our product: brand new original packaging

Our warranty: All new or repaired parts have a 12 month warranty period beginning

Our payment: 100% telegraphic transfer of inventory items before shipment, conditions can be proposed!

If you have any downtime spare parts that you cannot find, please feel free to call or use email to contact me. If there are issues that the product cannot solve, please contact me. Product prices can be negotiated. Please do not consider contacting me!