Description

Enhanced monitoring system of voltage transformer

Voltage transformer is a key and expensive component of the power grid, which is usually the most valuable equipment in the substation. Their reliability and availability are key to cost-effective generation and transmission. Continuous real-time monitoring is increasingly becoming an important part of hardware management solutions. Real time monitoring is very important for evaluating and understanding transformer performance and its safe operation.

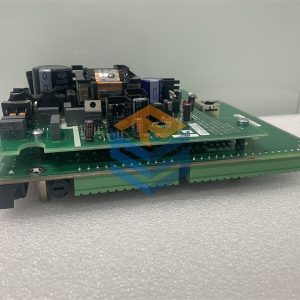

Intellix MO150 is a real-time monitoring system for transformers. It continuously measures key parameters, such as oil temperature, load current, water content and cooling device status. It includes independent mathematical model calculation based on the standard, which converts the original data into additional useful information to control the general state of the transformer. This information can also help system operators make key operational decisions, especially for the safety load of transformers whose service life is about to end.

Intellix MO150 can be equipped with its own DGA (oil soluble gas analyzer) sensor for a single gas for use as an independent system, or it can be integrated into Kelman Transfix’s DGA gas analyzer for multiple gases. ™ The combination of GE MO150 system and Transfix equipment provides customers with a complete solution, provides more detailed images of the overall status of transformers, and controls the root causes of most transformer failures.

Main advantages

Provides key information based on temperature and humidity data, which is complementary to the analysis of gases dissolved in oil.

Information comes from a mathematical model that conforms to IEEE standards ® C57.91 and calculated using the special characteristics of the transformer obtained from the passport data and test report.

The main direction is the performance of insulation system and the possibility of safe dynamic loading of transformer.

It also provides control equipment for the voltage regulator (RPN) and cooling system under the load of the power transformer.

According to the maintenance strategy, provide help for the transformer to optimize operation and determine the best conditions.

application area

Intellix MO150 is very suitable for intensive monitoring of key equipment (such as generator step-up transformer (GSU)), with special attention to aging of its insulation system.

It is often used for transformers, which are often overloaded due to incorrect dynamic load model. For example, when one enterprise sells energy to another, operators need to continue to supply power at critical moments to ensure that they safely overload transformers.

In some cases, MO150 provides more suitable cooling control than some other systems installed in older transformers. This capability provides new load space for older transformers and provides higher reliability by controlling cooling efficiency.

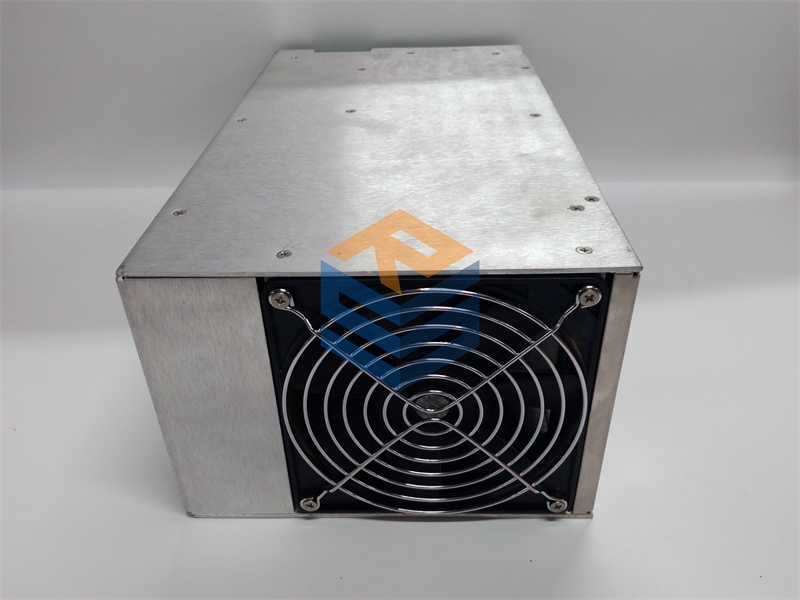

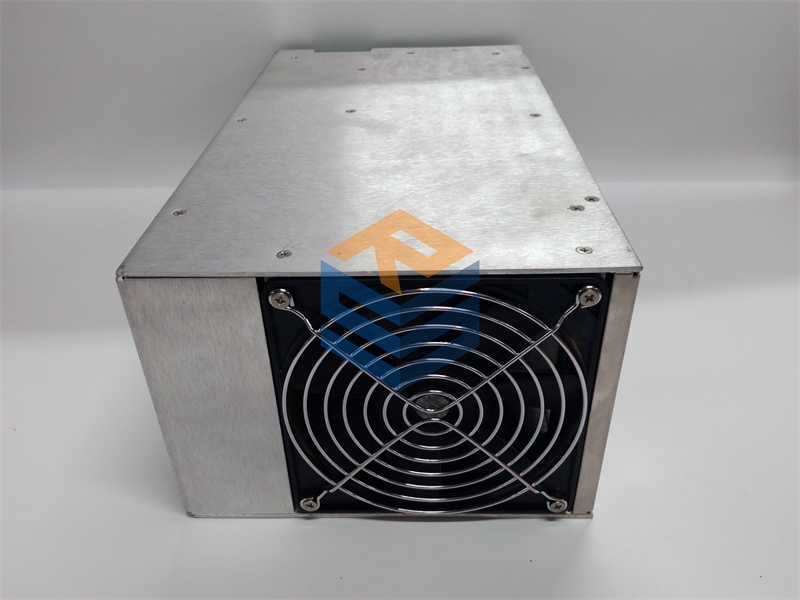

INTELLIX MO150

All prices listed on the official website are subject to confirmation by contact: Wu Jiedong (manager).

Our product: brand new original packaging

Our warranty: All new or repaired parts have a 12 month warranty period beginning

Our payment: 100% telegraphic transfer of inventory items before shipment, conditions can be proposed!

If you have any downtime spare parts that you cannot find, please feel free to call or use email to contact me. If there are issues that the product cannot solve, please contact me. Product prices can be negotiated. Please do not consider contacting me!