Description

Product Name:

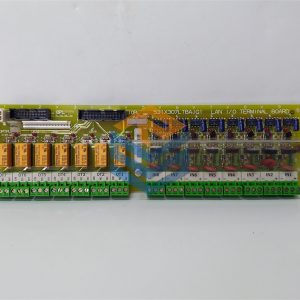

GE IS200TBCIH1CCD — Turbine Blade Condition Monitoring (TBCI) Interface Module

Product Description:

The GE IS200TBCIH1CCD module is an integral component of the GE Mark VIe system used for monitoring the condition of turbine blades in power plants. This module helps in the early detection of issues with turbine blades by integrating sensor data, which is then processed and analyzed for potential failures or performance degradation.

The IS200TBCIH1CCD is a condition monitoring interface card used to gather turbine blade health information. This data is used to optimize maintenance schedules, prevent failures, and improve overall system reliability. The module is designed to interface with various turbine health monitoring sensors and communicate the data to the central control system.

Product Parameters & Specifications:

- Module Type: Digital interface card for turbine blade condition monitoring

- Communication Protocol: Typically communicates via GE’s proprietary protocols, compatible with the Mark VIe control system.

- Input/Output: Handles data from various sensors designed to monitor turbine blades, including vibration sensors, strain gauges, and temperature sensors.

- Voltage Range: Typically operates within a voltage range compatible with the Mark VIe system’s power supply.

- Connectivity: Uses industry-standard connectors and supports integration with other control system components, including I/O modules and other diagnostic equipment.

- Dimensions: Standard rack-mounted or DIN rail-mounted form factor (specific dimensions depend on the system).

- Environmental Specifications: Designed for industrial environments, capable of operating under typical plant conditions (temperature, humidity, etc.).

Product Use:

The GE IS200TBCIH1CCD module is primarily used for:

- Turbine Blade Monitoring: Collects and processes sensor data to detect early signs of damage or wear in turbine blades.

- Condition Monitoring: Provides real-time data that can be used to predict maintenance needs, preventing unexpected downtime and optimizing the performance of turbines.

- Integration with Mark VIe Systems: The module is designed to work seamlessly with the GE Mark VIe control system, which is widely used in industrial turbine and power generation applications.

- Data Collection & Analysis: The module interfaces with multiple sensors (such as accelerometers, strain sensors, and temperature probes) and provides comprehensive monitoring of turbine health, thus ensuring safe and efficient operation.

- Maintenance Optimization: Supports predictive maintenance strategies, reducing operational costs and enhancing system reliability.

Key Features:

- Real-time turbine blade condition monitoring

- Integrated with GE’s advanced Mark VIe control systems

- Reliable and efficient data collection for proactive maintenance strategies

- High compatibility with industrial-grade sensors

- Supports a wide range of turbine health sensors (vibration, temperature, strain, etc.)

- Can be configured and diagnosed via the system’s software interface

GE+IS200TBCIH1CCD

| 6FC5210-0DF02-0AA0 PLC |

| 114RR-BA-000-000 PLC |

| 6SN1145-1AA01-0AA1 PLC |

| 5PP320.1214-39 PLC |

| REM610REM610C11HCMP02 PLC |

| 6AV7240-1AB07-0HA0 PLC |

| D674A906U01 PLC |

| PCI504-1022-4 PLC |

| MPSC-2000 PLC |

| 499ACL-01-54-60 PLC |

| 1FT6105-8AB71-1AA0 PLC |

| PCI5565-GE PLC |

| SERVOSTARTM603S60300 PLC |

| IC200CPUE05 |

| 1336-CAP-SP15A |

| DCS33-33E PLC |

| HMD01.1N-W0012-A-07-NNNN PLC |

| 6FC5210-0DF31-2AB0 PLC |

| DSB2S154-211E-000H PLC |

| 3NC154.60-2 PLC |

| PXI-6225 |

| 2711-K9C1 CPUI/O |

| MAC112D-0-FD-2-C/130-A-2/S013 PLC |

All prices listed on the official website are subject to confirmation by contact: Wu Jiedong (manager).

Our product: brand new original packaging

Our warranty: All new or repaired parts have a 12 month warranty period beginning

Our payment: 100% telegraphic transfer of inventory items before shipment, conditions can be proposed!

If you have any downtime spare parts that you cannot find, please feel free to call or use email to contact me. If there are issues that the product cannot solve, please contact me. Product prices can be negotiated. Please do not consider contacting me!