Description

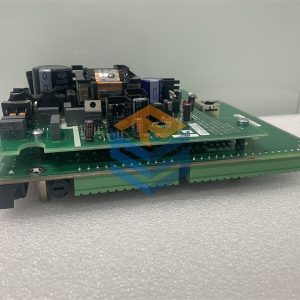

The IS215UCVGM06A developed by General Electric is a UCV Controller designed as a component for the Mark VI system. The MKVI was created for the management of gas and steam turbines. This board is one of five versions of UCV controllers available for the Mark VI system and is a single-slot version that can be used as a direct replacement for any previous controller version. It does not require a backplane upgrade when replacing an earlier-version controller and is instead installed in the VME rack using the connected bus for communication purposes.

The board uses an Intel Ultra-Low Voltage Celeron 650 MHz processor chip that has 128 MB of flash memory and 128MB of SDRAM. It is built with a front faceplate full of components that include a reset switch, a monitor port, a keyboard or mouse port, two COM ports (located side-by-side,) two Ethernet ports labeled LAN 1 and LAN 2, two individual USB connectors, four status LEDs located side-by-side and an opening labeled ? PMC.? Each of the Ethernet ports includes their own two status LEDs.

This board also includes a backplane connector and several vertical connectors and was built with small auxiliary boards, ready to accept auxiliary boards when they are attached. Additionallty the board is populated with jumper switches, capacitors, inductor coils, oscillating chips, crystal oscillators and integrated circuits.

It can replace the traditional relay circuit to realize logic control and sequence control. It can be used not only for the control of a single device, but also for multi machine group control and automatic assembly line. Such as injection molding machine, printing machine, stapling machine, modular machine tool, grinder, packaging production line, electroplating assembly line, etc.

industrial process control

In the industrial production process, there are some continuously changing quantities (i.e. analog quantities), such as temperature, pressure, flow, liquid level and speed. PLC uses corresponding A/D and D/A conversion modules and various control algorithm programs to process analog quantities and complete closed-loop control. PID regulation is one of the most widely used regulation methods in general closed-loop control systems. Process control is widely used in metallurgy, chemical industry, heat treatment, boiler control, etc.

IS215UCVGM06A

All prices listed on the official website are subject to confirmation by contact: Wu Jiedong (manager).

Our product: brand new original packaging

Our warranty: All new or repaired parts have a 12 month warranty period beginning

Our payment: 100% telegraphic transfer of inventory items before shipment, conditions can be proposed!

If you have any downtime spare parts that you cannot find, please feel free to call or use email to contact me. If there are issues that the product cannot solve, please contact me. Product prices can be negotiated. Please do not consider contacting me!