Description

Manufacturer : ICS Triplex

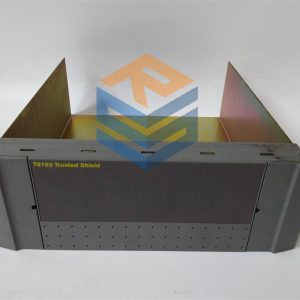

T8461

System Supply Voltage Range : 20 to 32Vdc

Circuit Type : Fault tolerant, fully triplicated with optional line

monitoring

Number of Outputs : 40 Channels

Independent Power Groups : 5 each of 8 outputs

Operational Output/Field Voltage Range : 18 to 60V dc

Output Voltage

Measurement Range : 0 to 60V dc

Maximum Withstanding : -1 to 60V dc

Output Current Rating ( Continuous ) : 0.75A per channel

6A per power group

Minimum On State Load Current : 25mA

Output Off State Resistance (effective leakage) : 33kP

Maximum capacitance Pre release 3.5: 30-55uF

Release 3.5: at least 3500uF at 0.75A

Flashing/pulsing current loads : Release 3.5 is recommended

Output On State resistance : 0.6P

Output Short Circuit Protection : Electronic (latching)

Channel to Channel Crosstalk : >-40dB

Power Consumption

Field Supply at 24V (0.75A per channel) : 18W

System Supply (24V) : 22W

Field Common Isolation

Sustained Working : ±250V dc

Maximum Withstanding : ±2.5kV dc

Output Turn-on/off Delay : 0.5ms

Sample Update Time : 0.5ms

Sequence of Events

Event Resolution : 1ms

Time-stamp Accuracy : ±0.5 ms

Self-Test Interval : 2 minutes

Intrinsic Safety : External barrier

Output Short Circuit Protection : Automatic

Operating Temperature : -5°C to 60°C (23°F to 140°F)

Non-operating Temperature : -25°C to 70°C (-13°F to 158°F)

Temperature change : 0.5ºC/min

Operating Humidity : 5 – 95% RH non-condensing

Environmental Specifications : Refer to Document 552517

Dimensions

Height : 266mm (10.5ins)

Width : 31mm (1.2ins)

Depth : 303mm (12ins)

Weight : 1.285kg (2.8lbs)

Shipping Weight : 2 Kg

PLC is a device specially developed for industrial automatic control. Usually, PLC uses “natural language” programming oriented to control process and problems. The products of different manufacturers use different programming languages, such as ladder diagram, statement table, control system flow chart, etc. In order to enhance the various operation functions of PLC, some PLCs are also equipped with BASIC language, and are exploring the use of other high-level languages for programming.

The PLC products produced by FANUC, Lishi, Mitsubishi and Fuji in Japan all adopt ladder diagram programming. When a programmer is used to input a program to the PLC, the general simple programmer uses the code table for input, and the large programmer can also use the ladder diagram for direct input. In many PLC products, due to different manufacturers, the representation method of the instruction system and the mnemonic in the statement table are also different, but the principle is completely the same. In this book, we take FANUC-PMC-L as an example to introduce the PLC instructions applicable to the control of CNC machine tools. In FANUC series PLC, the specifications and models are different, but the number of functional instructions is different. For example, there are 23 FANUC-BESK PLC-B functional instructions developed jointly by Beijing Machine Tool Research Institute and FANUC Company. In addition, the instruction system is completely the same.

All prices listed on the official website are subject to confirmation by contact: Wu Jiedong (manager).

Our product: brand new original packaging

Our warranty: All new or repaired parts have a 12 month warranty period beginning

Our payment: 100% telegraphic transfer of inventory items before shipment, conditions can be proposed!

If you have any downtime spare parts that you cannot find, please feel free to call or use email to contact me. If there are issues that the product cannot solve, please contact me. Product prices can be negotiated. Please do not consider contacting me!